In the realm of automation in the industrial sector, integration of robotic arms has been viewed as an transforming force, changing the manufacturing landscape and manufacturing processes. Modern technology has made robotic arms, sometimes referred to Arm robots industrials indispensable tools. They offer unmatched precision, efficiency and safety in many industries. This article focuses on the capabilities of robot arms. It also examines their role in the current business world as well as the recent developments in automation for industrial use.

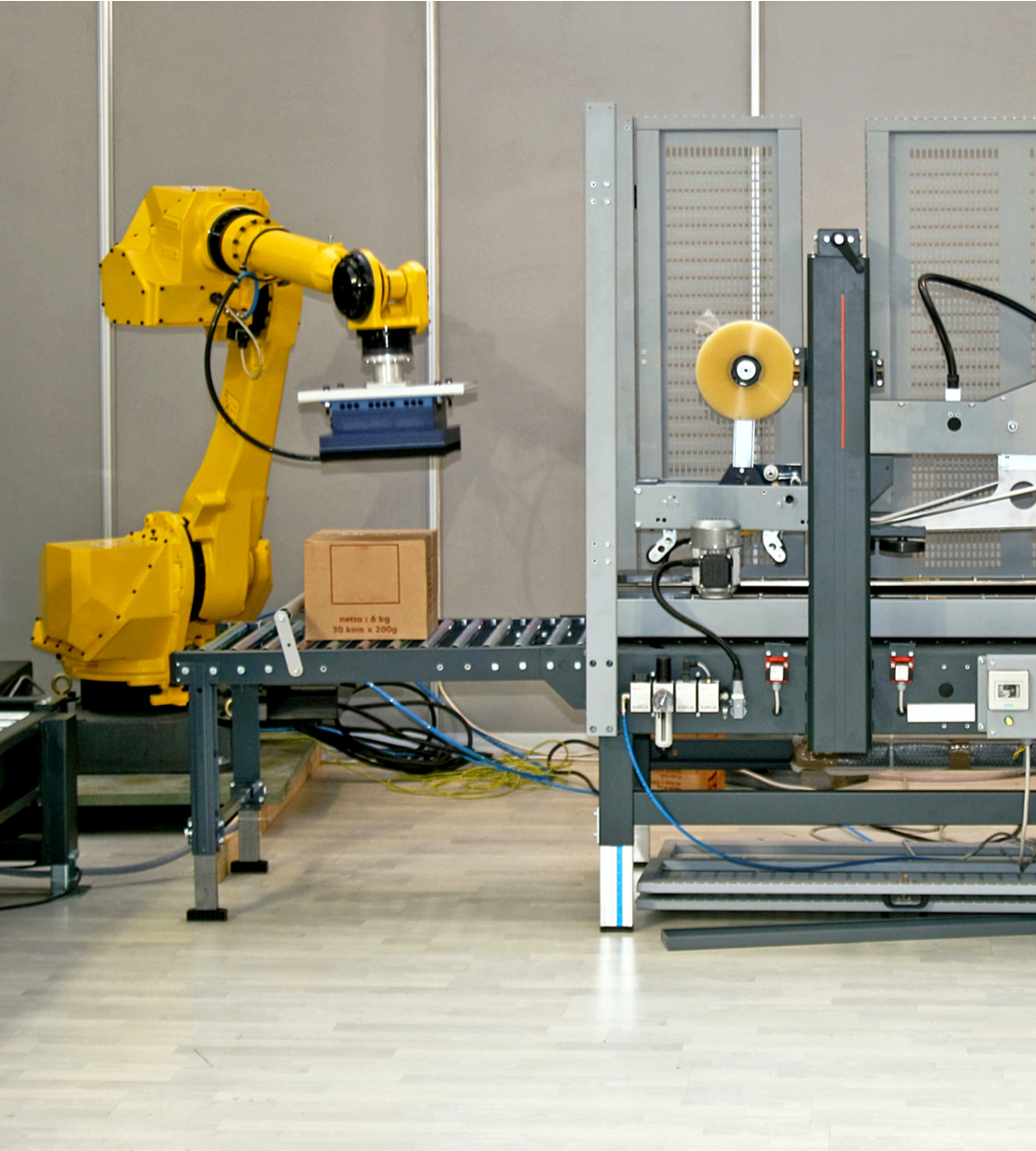

Robotic arms are mechanical devices that replicate the functionality of human arms, but with more power and precision. They are utilized in many industries, including electronic assembly, automotive manufacturing and pharmaceuticals. They are capable of performing repetitive, complex tasks with incredible precision. Robotic arms can be programmed to perform tasks. arms allows for seamless integration into various production environments. They offer flexible motion as well as the flexibility to accommodate a variety of operational demands.

The robotic arm firms are a cornerstone for the modern day automation. They are a complex and kinematic system of joints that can be moved that can rotate as well as linear displacements, which comes with amazing dexterity. The robotic arm can navigate complex spatial configurations, manipulate objects with great precision and ensure the safety of human operators. In response, robotic arms are now considered indispensable by industry. They streamline production and increase efficiency.

The utilization of end effectors by robotic arms, which are the functional equivalents to human hands, is among the most distinct features of robotic arms. These end effectors are usually specifically designed for specific tasks play an essential role in determining the nature of robotic arms’ applications. Robots that are equipped with end effectors that are specifically designed to perform specific tasks, can accomplish a variety of tasks. From lifting and gripping large objects to carefully making intricate pieces, robotic arms equipped with end effectors that are specifically designed are able to accomplish these tasks with unprecedented efficiency and accuracy. For more information, click Robotic Arm

The integration of robotic arms in industrial automation has led to the dawn of a new age of productivity and technological innovation. Robotic arms help businesses optimize their manufacturing processes to reduce human error and enhance the quality of products. The seamless integration between robots and automated systems has led to significant improvements in efficiency, allowing companies to respond to growing demands with unparalleled speed and accuracy.

The effects of robotic arms go beyond the simple automation. It encompasses a fundamental shift in the definition of industrial processes. Industrial robotics have not only revolutionized manufacturing processes, but also opened the door to innovative production techniques. Robotic arms can perform in hazardous and challenging situations. This has enhanced worker safety while unlocking new opportunities for manufacturing processes that are complex.

The advancement of technology for robotic arms has resulted in the creation of end-effectors made to meet specific needs of industries. These end-effectors feature advanced gripping and sensory capabilities, which have also increased the variety of applications for robotic arms.

Businesses in Australia are in a unique position to boost their competitiveness as well as operations capabilities by taking on the potential of automation using robotic arms. The integration of robotic arms into industrial workflows will enable sustainable growth, increase overall productivity and dramatically transform manufacturing. With an emphasis on efficiency and precision, robotic arms are poised to explore new frontiers in automation for industrial processes, enabling businesses to achieve unparalleled levels of operational efficiency.

In conclusion, the introduction of robotic arms, also known as industrial robotic arms, is an important step in the development of industrial automation. The precision, adaptability, safety, and versatility of robotic arms has redefined manufacturing capabilities in today’s times providing businesses with an edge on a market that is becoming more competitive. Businesses will reap the benefits as Australia adopts robotic technology. This will result in higher productivity, improved efficiency and the ability to innovate.