Machining is always about speed, precision and dependability, but in the highly competitive manufacturing industry efficiency is the most important factor. Whether you’re manufacturing automotive components such as aerospace components or high-tech electronic components, the tools you choose directly affect your final results. The indexable drill high-speed drill, tungsten carbide inserts and threading tools all make a difference.

These aren’t just upgrades of older tools. These new tools allow for the most efficient method of working that reduces the time it takes to work, decreases costs and produces better results using less effort. Take a look at each one and consider how they can help companies drill deeper, cleanly cut, and get the job done faster.

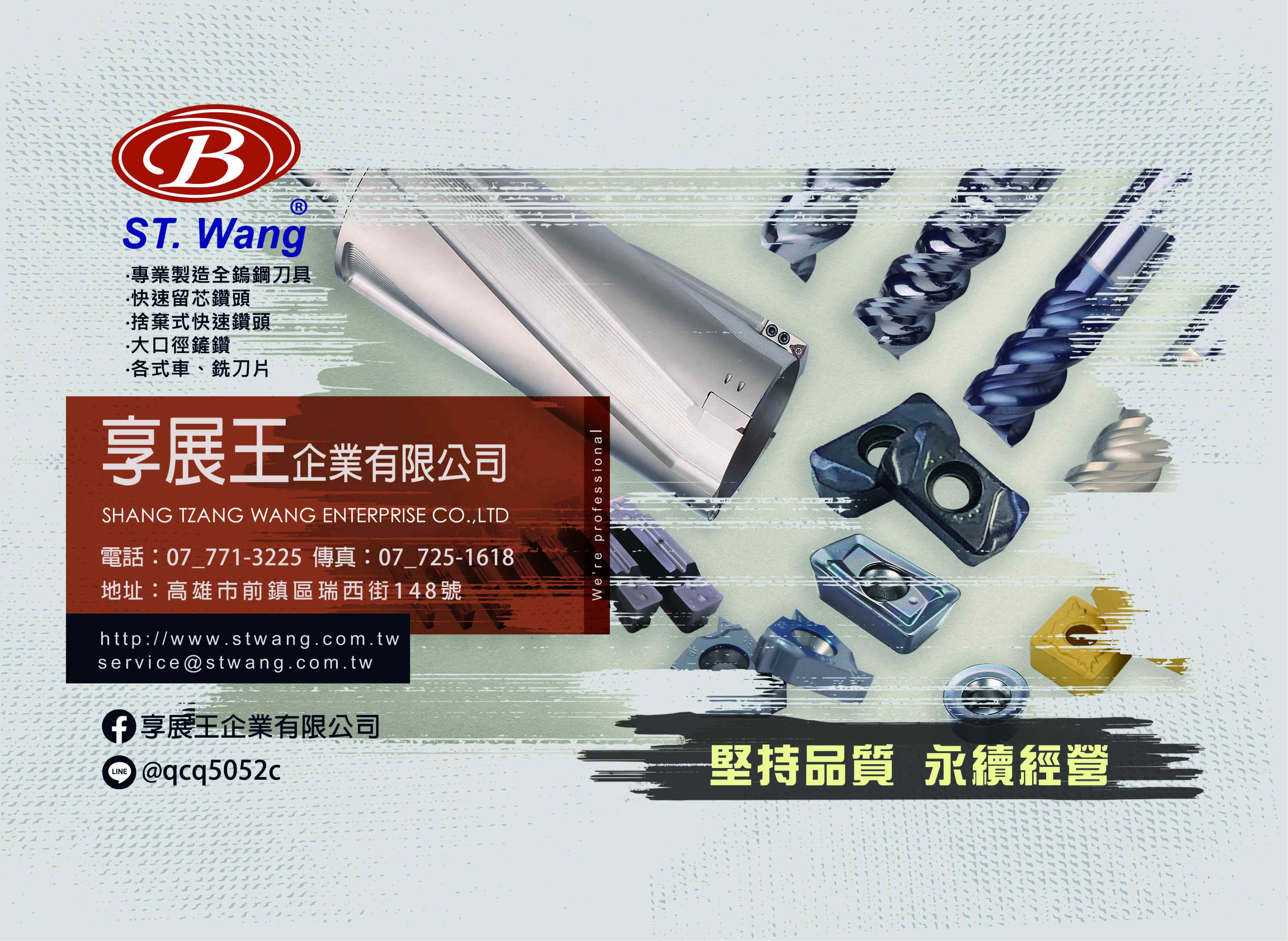

Image credit: stwang-tw.com

Indexable Drills: More Holes, Less Hassle

Drilling holes of a large size used to be costly and lengthy. Drills that were solid had to be sharpened, wore quickly and caused a slowdown in the process. That’s why more machinists are shifting to an indexable drill. You can change inserts, not the whole drill when it starts to wear out.

Indexable drills are well-known for their efficiency. The drills are made to last, come with robust design and require little maintenance. You can reduce use, keep your tools inventory at a minimum, and prolong the life of your machines with the use of replaceable inserts. SHANG TZANG WANG ENTERPRISE, CO., LTD offers disposable core-stays that offer consistent performance for large-diameter application. This upgrade is ideal for shops who perform repetitive hole-machining. They can cut down on many hours of work every week.

High Speed Drills – Designed to Meet the Current Demands

High-speed drills are utilized in production environments where speed is of the essence. They are made to work fast and accurately without compromising on speed. They’re able to work with robust materials and quick cycles. They are utilized to make everything from large-volume automobile parts to precise medical devices.

Modern high-speed drills have optimised flute designs and cutting-edge coatings that resist heat buildup, reduce friction, and lengthen tool life. This means less damage as well as fewer changes to the tool and more tools out the doors. If you’ve had any issues with a broken drill in the middle of your process switching to high-speed drills could be a great moment of discovery.

Tungsten Carbide End Mills: Reliable Performance Cut After Cut

When it comes to milling, tungsten carbid end mills are the most reliable tool that are used on the shop floor. These end mills are famous for their heat resistance and hardness. They can also mill through tough materials without losing edge sharpness. These tools are reliable for every task such as roughing large sections to finishing corners.

The flexibility of tungsten carbide is what makes them so special. With various flute counts, angles for helixes and coatings, they are able to be adapted to a broad variety of applications from aluminum to titanium. For machinists who require precision and longevity, carbide end mills can provide the perfect combination of aggressive material removal and clean finish.

Threading Inserts: Tiny Tools, Big Impact

Threads’ creation may appear as a small part of the process, but this is one of the most significant. A poor thread can ruin any part that’s flawless. That’s why a high-quality threading insert matters. These small, replaceable tools are designed to cut both internal or external threads with a high degree of accuracy and precision.

Threading inserts, as opposed to conventional taps and dies that wear out in a variety of ways, offer the same results. The tool can be indexed to the next cutting edge when one edge has become dull. There’s no need to remove it or regrind. It’s fast, easy and economical. The reliability of threading inserts are important for machine operators. With the right insert you can be sure that your threads will work the first time. There will be no second passes, no rework and there is no worry about the possibility of part rejection.

The Bottom Line

In modern machining, time is a commodity you don’t have the money to waste. The most efficient shops of today are focusing on smarter and more flexible machines. These cutting tools are of the most advanced design and do more than just improve accuracy; they make workflows easier, speed up changes, increase life and improve accessibility. What’s the end result? There is less time spent on troubleshooting, and more time spent the production of high-quality components. In an industry that has higher demands and tighter margins are the norm having tools that work smarter gives manufacturers the edge they need to remain competitive.